Product description

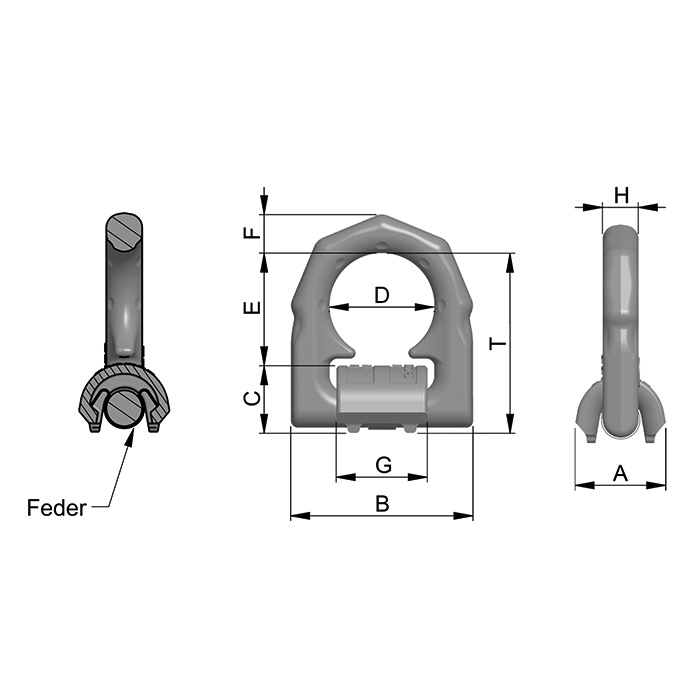

The LPW weldable lashing point is a robust and reliable anchor solution designed for securing heavy loads across a wide range of industrial and transport applications. Engineered for permanent welding onto flat steel surfaces such as trailers, containers, construction equipment, or transport vehicles, the LPW provides a solid and secure lashing point. Manufactured from high-strength steel, the LPW is built to withstand high lashing forces and extreme working conditions. Its large load-bearing capacity makes it ideal for demanding environments where safety and performance are paramount. The design ensures smooth attachment of lashing chains or straps, helping to simplify the securing process. The LPW is commonly used in construction logistics, RoRo shipping, and freight transport, offering a long-lasting solution that meets modern safety standards. When welded correctly, it delivers consistent reliability, even under dynamic load conditions. • Manufactured from VIP material, up to 50%higher lashing capacity than conventional design• Sleek design, zinc-phosphated• Weld-on block is marked with LC in daN• Also available with spring for noise reduction• Optimised 90° load support• 2 patented lugs in the eye improve hook fit