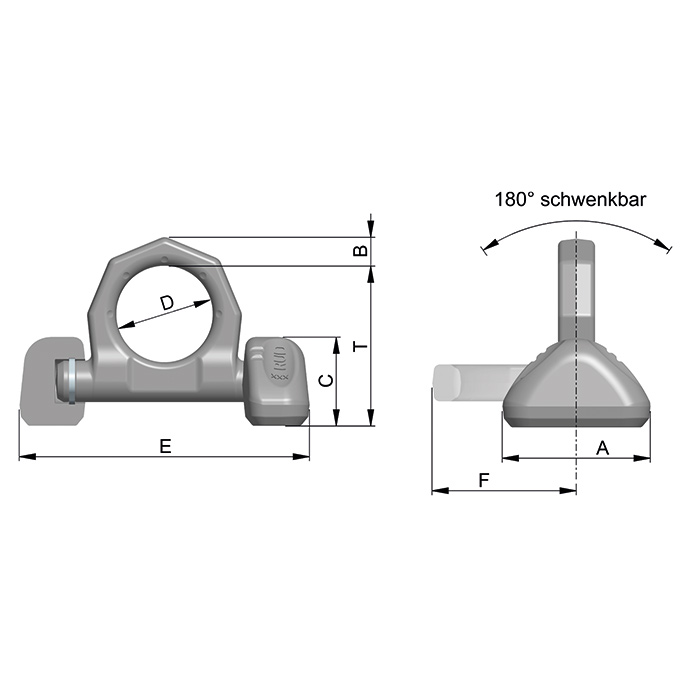

Product description

The LRBS-FIX weldable lashing point is a heavy-duty, fixed-position anchor point designed for securely fastening loads in industrial, construction, and transportation environments. Engineered for permanent installation, it is welded directly onto the load-bearing structure, offering a reliable and tamper-resistant lashing solution. Manufactured from high-grade steel, the LRBS-FIX provides outstanding strength and durability. Its compact design ensures easy integration onto trailers, truck beds, containers, and heavy machinery. With a high permissible lashing capacity, it meets the demands of securing even the most challenging loads. The LRBS-FIX is ideal for applications where a fixed lashing point is required and space or movement is limited. It’s compatible with a wide range of lashing chains, hooks, and straps, making it a versatile addition to any secure load-handling system. • Circular HY welding seam• No subsurface corrosion of the weld-on blocks• Weld-on blocks and ring bracket are connected by radial clamping spring – Easy adjustment of ring backet – Ring bracket remains in position – Easy painting in the gap – No loose parts – No rattling – Secured welding process: dimension E is predetermined