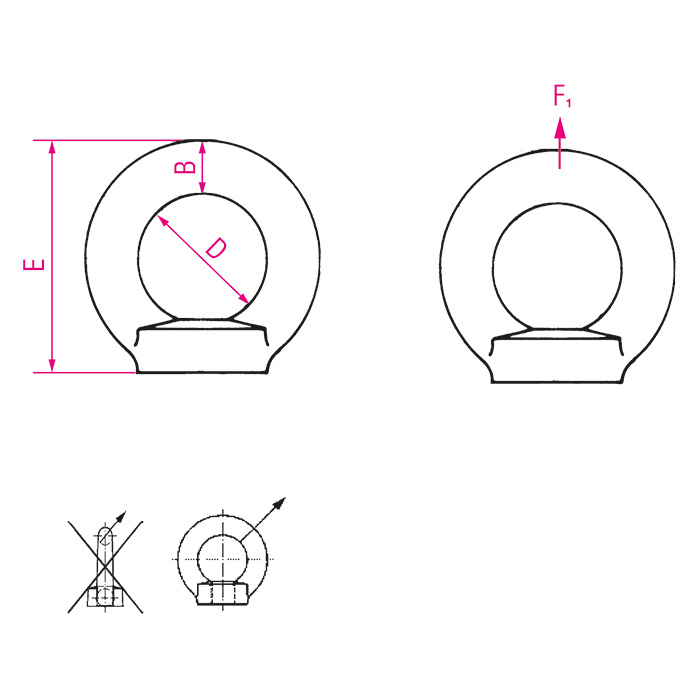

Product description

The Eye Nut according to DIN 582, galvanised is a robust and standardised lifting and fastening solution designed for safe and efficient load handling. Manufactured in accordance with DIN 582 specifications, this eye nut ensures compatibility with lifting equipment and adherence to recognised safety norms across industrial and commercial applications. Made from high-grade steel and protected with a galvanised finish, it offers excellent corrosion resistance and durability, making it ideal for both indoor and outdoor environments. The galvanisation extends the product's lifespan, even under harsh or demanding conditions. Screwed onto threaded bolts or studs, the eye nut creates a strong anchor point for hooks, ropes, slings, or chains. It is particularly suitable for overhead lifting, rigging operations, and securing machinery or components during transport or assembly. Available in a range of thread sizes and load capacities, the DIN 582 galvanised eye nut is a reliable choice for construction, shipping, logistics, and engineering sectors, offering safe load handling and operational efficiency. Material: C15E Please observe mounting instructions acc. to DIN 582! Ring nuts must: Be screwed in fully• Lie evenly and fully on the contact surface• Be positioned in such a way that avoids side drag• Be subjected to loads in the direction of the ring plane