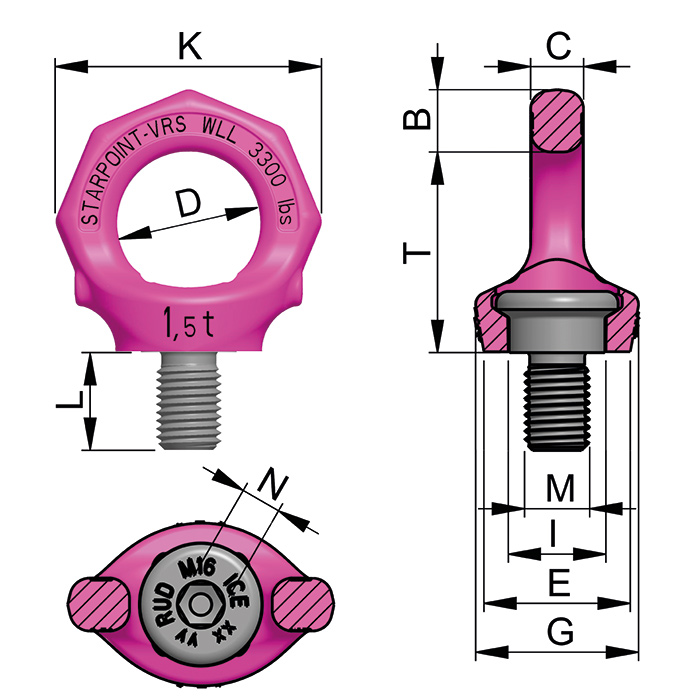

Product description

The VRS eye bolt with a 16,000kg working load limit and M56x84mm thread is a heavy-duty swivel lifting point designed for demanding industrial lifting applications where very high load capacity, flexibility and precise load alignment are essential. It is suitable for use in heavy engineering, construction, transport, manufacturing and maintenance environments where controlled lifting and rotational movement are required.

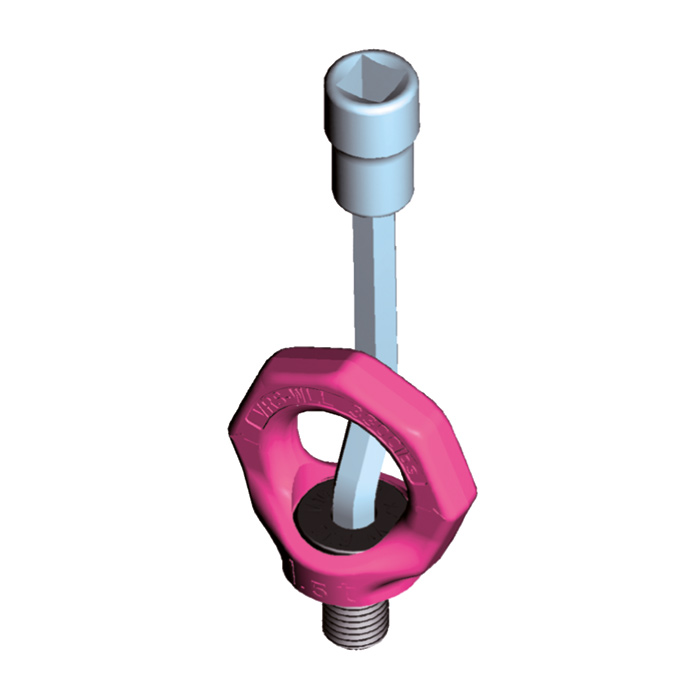

Unlike conventional DIN 580 eye bolts, the VRS features a distinctive star-shaped design and a fully rotatable load ring that automatically aligns with the direction of force. The load ring rotates freely through 360° and pivots through 180°, allowing the full working load limit to be utilised in any pull direction while eliminating the risk of side loading, bending stresses or incorrect alignment, even in complex lifting scenarios.

Manufactured from high-strength forged alloy steel (material 1.6541) and tempered for durability, the VRS eye bolt is 100% electro-magnetic crack-tested in accordance with DIN EN 1677-1. The integrated captive hexagon socket screw allows secure installation into threaded holes, provided the mounting material is at least St37 and the thread bore is countersunk to the nominal thread diameter. Once installed, the lifting point must rotate freely through 360° to ensure correct and safe operation.

Finished in RUD’s fluorescent pink powder coating, the eye bolt provides corrosion resistance and high visibility in harsh industrial environments. The working load limit is clearly marked for all load directions, supporting correct product selection and safe use on site. With a safety factor of 4 and suitability for operation down to -40°C, the VRS eye bolt delivers reliable performance across a wide range of demanding working conditions.

Compatible with lifting slings, chains and hooks, the 16,000kg VRS eye bolt is ideal for lifting and positioning heavy machinery, structural components and large assemblies where controlled rotation and directional load control are critical. When used in accordance with applicable standards, inspection requirements and site safety procedures, it supports safe and efficient lifting operations in professional industrial settings.