Product description

The VRM StarPoint eye nut with a 100kg working load limit and M6x11mm thread is a compact, high-performance swivel lifting point designed for safe and controlled lifting of light loads. Manufactured by RUD, it is suitable for professional applications in engineering, manufacturing, logistics and maintenance where precise load alignment and operational safety are essential.

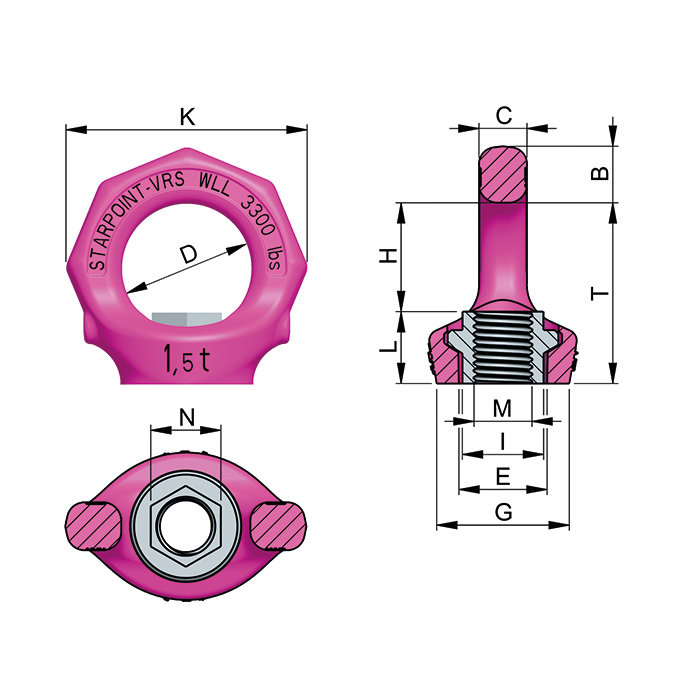

Unlike conventional eye nuts, the VRM features a pivoting and rotating load ring that allows full 360° rotation and 180° pivoting. This design ensures the lifting ring automatically aligns with the direction of pull, enabling the full working load limit to be utilised in any load direction. By preventing side loading, bending stresses and incorrect force application, the VRM significantly improves safety compared with fixed eye nuts.

The eye nut is forged from high-strength alloy steel and finished with RUD’s distinctive VIP pink coating, providing corrosion resistance and high visibility in industrial environments. Each VRM eye nut is crack-tested and clearly marked with its working load limit and thread size, supporting traceability and correct product selection in safety-critical lifting operations.

Designed for use with threaded studs or bolts, the VRM must be mounted on a flat, plane surface to ensure full contact between the eye nut and the workpiece. The internal thread must be fully engaged, and load capacity ratings are only valid when used with bolts of at least grade 10.9. Once tightened, the body of the eye nut must rotate freely through 360°, and the lifting ring should be aligned in the direction of pull before attaching lifting equipment.

Suitable for operation at temperatures down to -40°C, the 100kg VRM StarPoint eye nut provides a reliable solution for light lifting tasks where directional flexibility, strength and safety are non-negotiable. When used in accordance with safe use instructions, inspection regimes and site safety procedures, it supports efficient and compliant lifting operations in professional industrial settings.