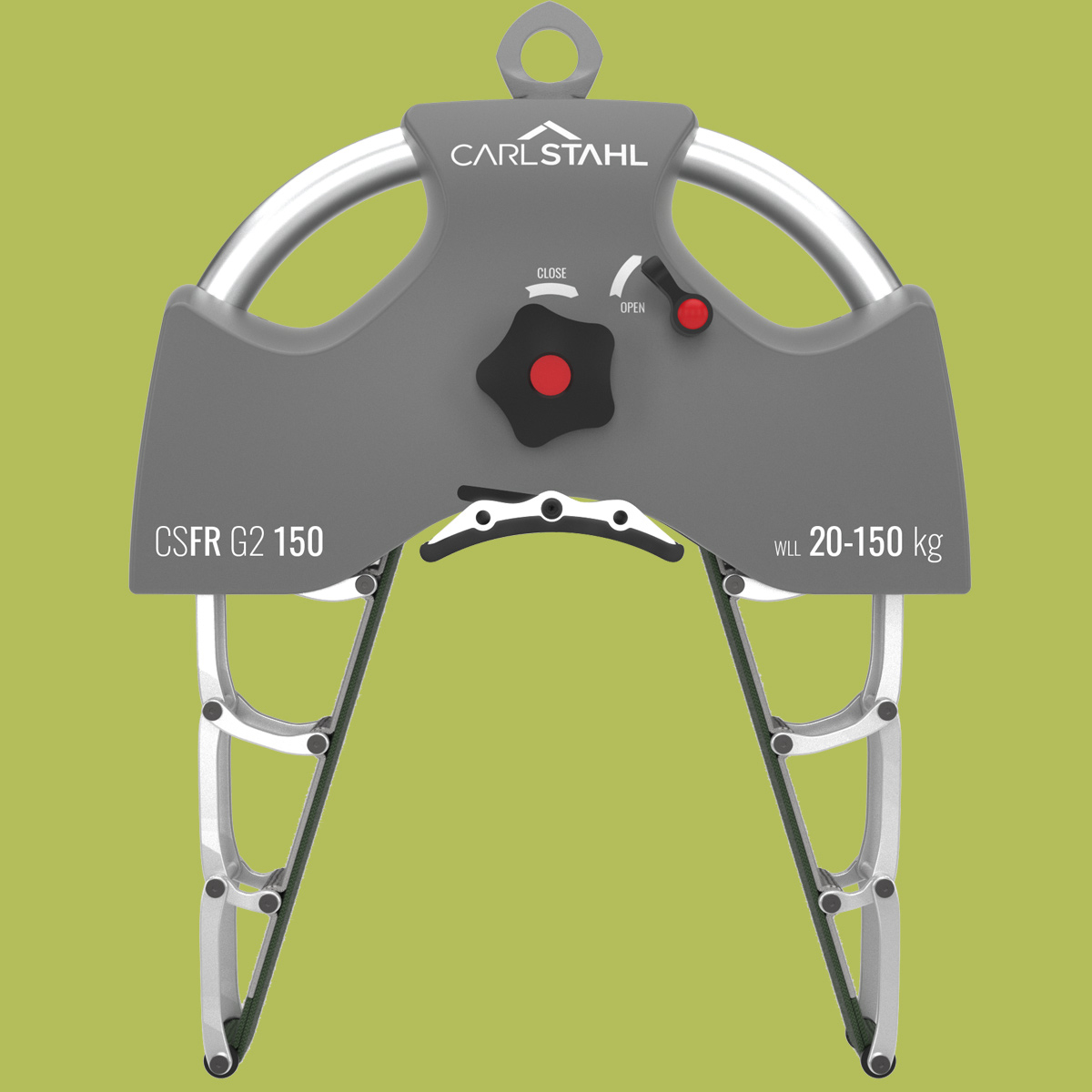

Bionic universal gripper CSFR G2 150 from Carl Stahl

Your solution for handling different load geometries and sensitive loads

Gripping and lifting loads with different geometries places high demands on the selection of suitable grippers, which is associated with high costs, extensive research, and complex decision-making processes. Particularly sensitive or fragile loads also require special solutions, such as soft contact surfaces or form-fitting grippers, to prevent damage or slipping during transport. Are you facing similar challenges? Are you looking for a gripper that can handle the complex requirements of your loads?

Our CSFR G2 150 universal gripper, developed based on bionic principles, offers you a unique combination of advantages thanks to its innovative design. It expands specific areas of application for demanding load handling and exceeds the performance limits of commercially available grippers. The CSFR G2 150 opens up new possibilities for your challenges!

View CSFR G2 150 in the webshop

The special features of the CSFR G2 150 universal gripper at a glance: What you need to know

High adaptability

Thanks to its bionically inspired self-adaptability, the CSFR G2 150 easily adapts to a wide variety of round and angular load geometries, ensuring a full-surface fit and safe handling.

Gentle gripping

The CSFR G2 150 enables gentle gripping, with even and low contact pressure preventing damage to the load.

Narrow gripping space

The functional principle of the CSFR G2 150 allows loads to be handled in narrow spaces, thus promoting efficient and space-saving storage.

The CSFR G2 150 bionic universal gripper from Carl Stahl is an innovative solution to standard grippers, expanding the range of specific applications for vertical lifting, transporting, and lowering of unguided loads. As a special special load handling device, the CSFR G2 150 offers flexibility for adaptive and gentle gripping of loads. The transfer of the biomechanical fin jet effect to a technical gripper ensures high adaptability when gripping loads of different shapes and diameters.

The form-fitting connection between the load and the gripper, in which only the inner fabric band is in contact with the load, ensures a gentle and careful hold with evenly distributed and low contact pressure, thus preventing damage. In addition, the functional principle of the gripper allows for efficient and space-saving storage of the loads.

Contact us!

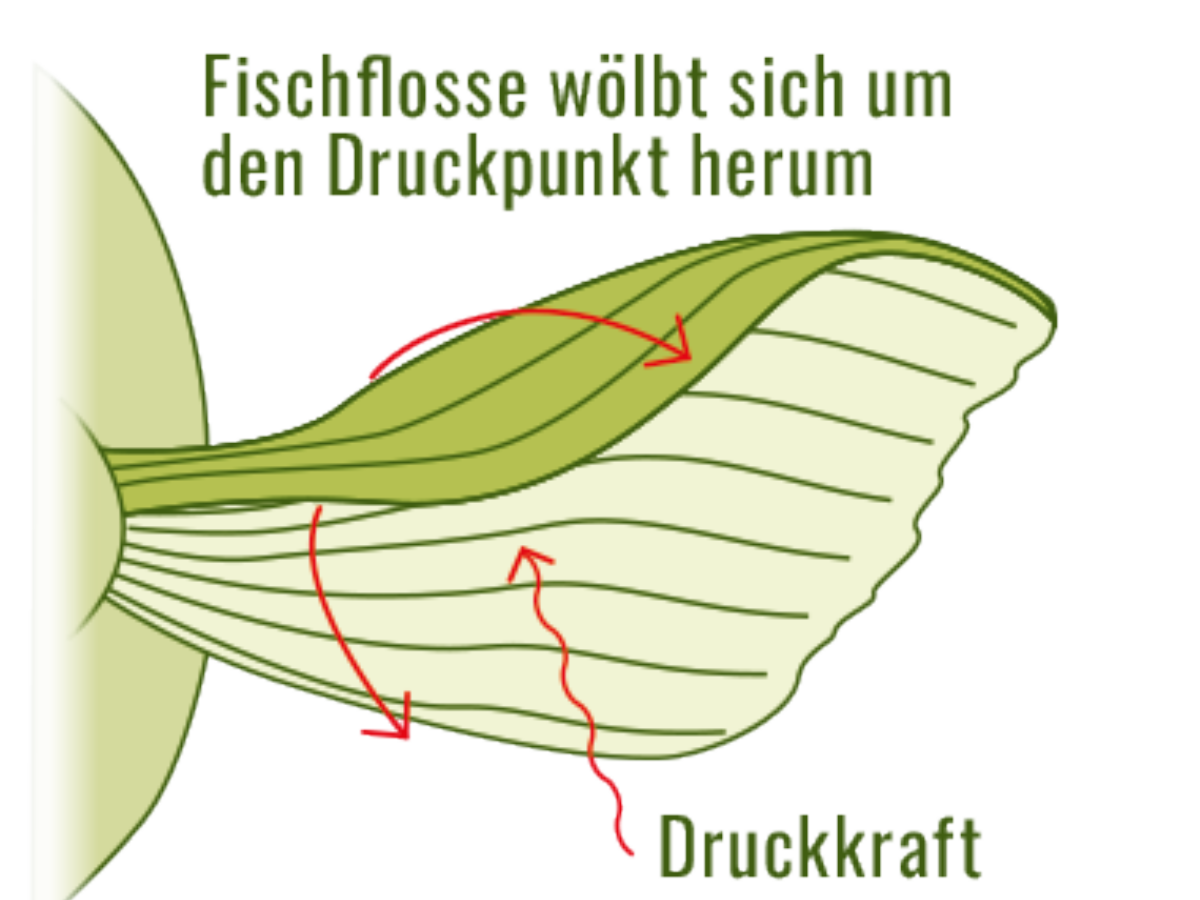

Bionic development approach

The CSFR G2 150 uses the fin ray effect, a concept borrowed from nature. This is a biomechanical concept that can be found in the structural design of a fish fin, among other places, and was named after it. When pressure is applied, the fish fin does not bend away from the pressure point as expected, but curves around it. In technology, this effect is used to develop flexible structures that can adapt to different loads or environments. General information about bionics can be found here.

Functionality and technical operation

The CSFR G2 150 universal gripper is manually operated. An attached star handle allows the gripper jaws to be closed, while the corresponding lever releases the lock and opens the gripper. A supplied hold-down device ensures three-point mounting for loads prone to tipping and increases the gripping range for small load geometries.

Reasons for using universal grippers

Gripping and lifting different load geometries

Grippers are available in a wide variety of designs. Each gripper is designed for a specific load, load shape, or application. The more different loads and load geometries have to be moved within a value chain, the more different types of grippers the user must have available. This comes with high costs. The need to select different grippers based on different load shapes and weights often requires extensive research and a significant time investment. The complexity of this process is further increased by the wide variety of grippers available on the market.

Each gripper requires individual operation and different requirements must be taken into account. This can be very demanding, especially if a user needs to be familiar with the specific applications of each individual gripper. In addition to the cost-intensive purchase of different grippers, their respective maintenance requirements must also be taken into account. To minimize these challenges, it may be advisable to select universal or adaptable grippers that can handle a wider range of loads and thus also reduce setup times.

Gripping and lifting sensitive loads

Finished and coated surfaces such as paint, powder, etc. are extremely sensitive and require special care when handling loads. If a gripper comes into contact with such loads during the gripping process, there is an increased risk of damage to the surface. Scratches or similar damage can impair the appearance and function of the load and must therefore be avoided at all costs.

Common solutions for gentle gripping of finished load surfaces include protective coatings inserted into the inner surface of a gripper or special protective covers for the load. However, these options usually require an additional work step and increase the time required. It is therefore advisable to choose grippers that have soft or rubberized contact surfaces with the load. In addition, special care must be taken when handling certain finished loads to ensure safety.

Oily surface coatings reduce friction between the load and the gripper, allowing the load to slip or come loose during transport. In this case, it is advisable to use a form-fitting gripper that allows the load to be gripped from below.

However, the requirements for handling sensitive loads are even more complex. In particular, loads that are not inherently stable or fragile pose major challenges. Thin-walled loads such as fabrics or paper, glass or porcelain objects are very sensitive to pressure, so force-free gripping is not recommended in these cases. A force-fit usually requires high contact pressure, which can compress or damage this type of load. Gentle and evenly distributed contact pressure can only be achieved through a form-fit and a large contact surface.

Efficient storage of loads

Efficient storage organization is crucial for facilitating access to and handling of loads. However, experience shows that in many cases, the available storage space is very limited. Insufficient space for storing loads usually leads to challenges with cumbersome and unsafe handling processes. Careful planning, organization, and implementation of storage systems are necessary to avoid such difficulties.

The use of special racking systems for confined spaces or investment in automated storage systems can offer solutions, but these also involve high costs. The selection of a suitable gripper is therefore often of great importance. Depending on the gripper and its operating principle, loads must be stored at varying distances. A gripper with a narrow gripping space can be advantageous here in order to save storage space.

FAQ’s

Who is the CSFR G2 150 suitable for?

In general, the CSFR G2 150 bionic universal gripper is designed for a wide range of applications in compliance with the technical data and load limits. The CSFR G2 150 is particularly recommended for use in situations where complex requirements are placed on the lifting, transporting, and lowering of loads. For example, when different load geometries need to be handled with one gripper and, at the same time, particularly gentle gripping of the loads is required.

How does the CSFR G2 150 differ from standard grippers?

Thanks to a unique combination of features that are otherwise only found in isolated cases in gripper systems, and in some cases only in special designs, the CSFR G2 150 offers the possibility for demanding handling applications.

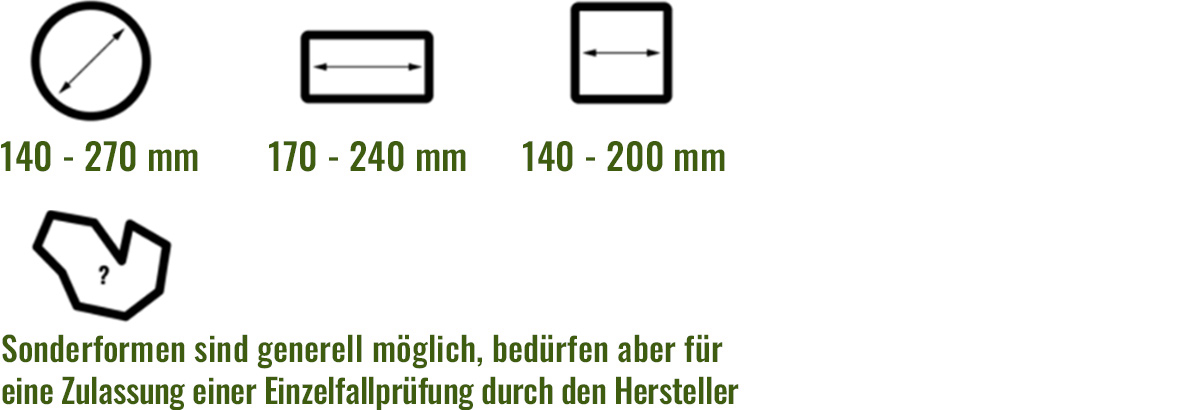

What limits must be observed with regard to load contours?

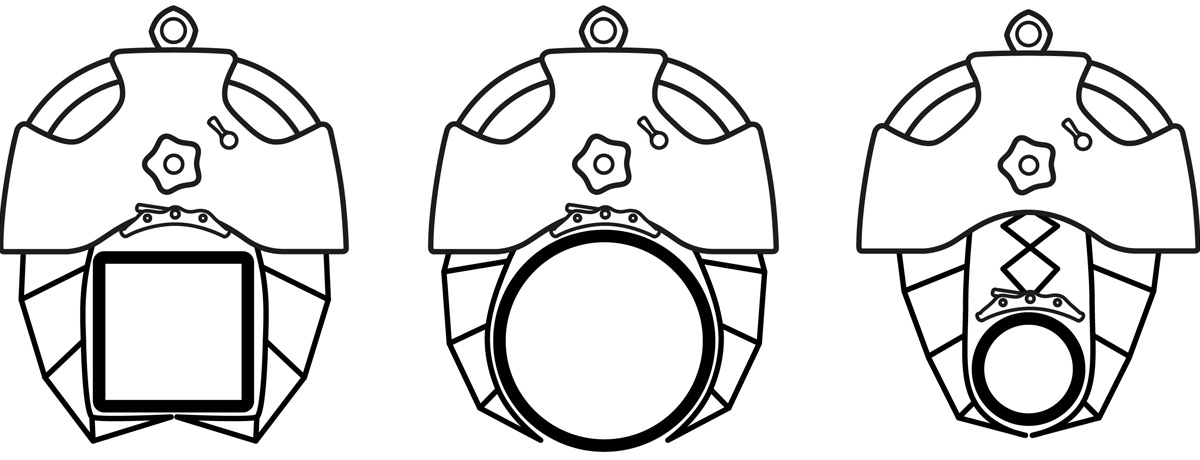

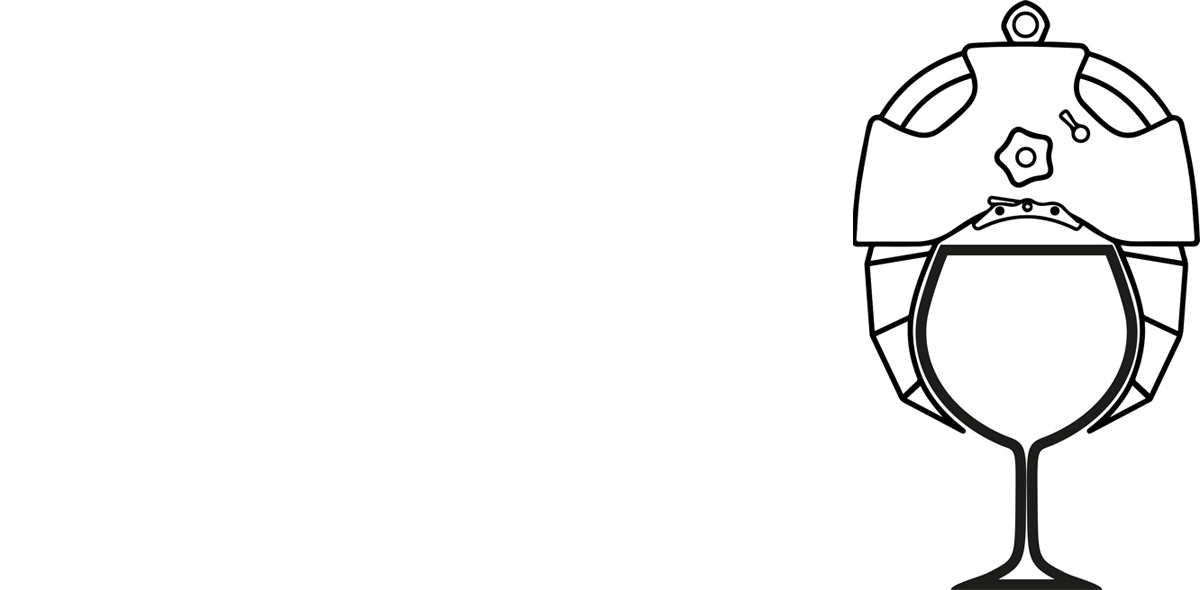

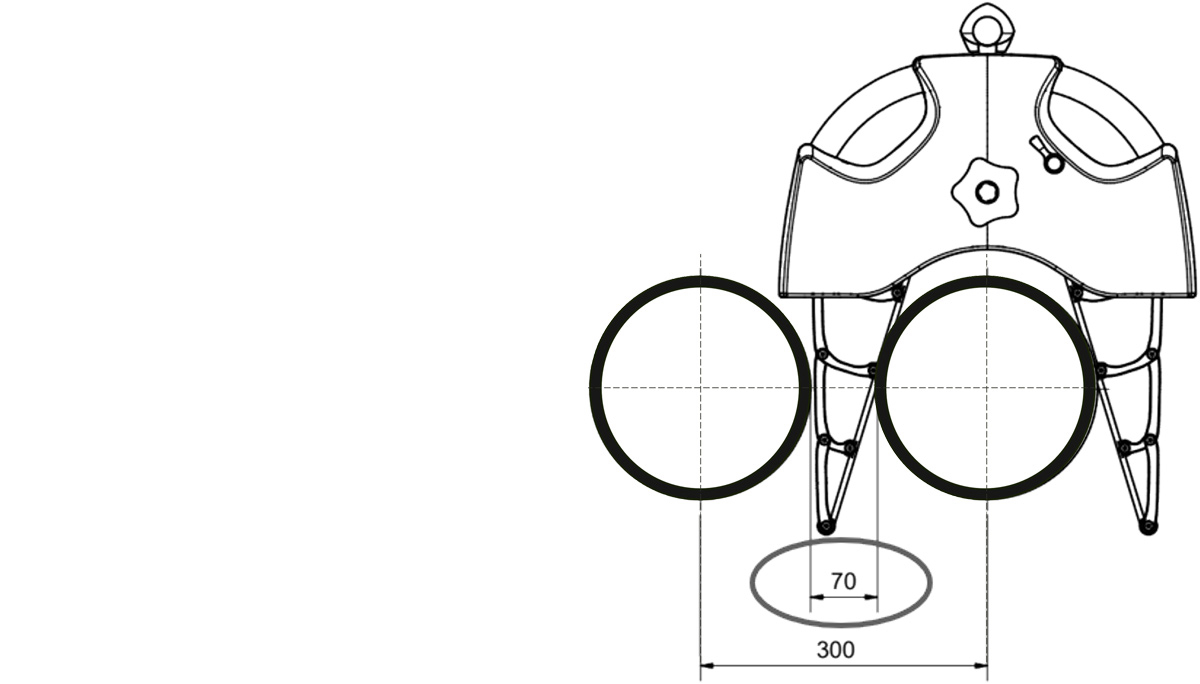

The CSFR G2 150 universal gripper offers flexible options for handling different load shapes and diameters. An abstract and simple representation of the defined load limits can be found in the figure. It should be noted that even approximately round loads, such as oval, hexagonal, or octagonal loads, etc., can be handled with the CSFR G2 150. Other special shapes are also available on request and after individual testing by the manufacturer using load samples.

When should I use the hold-down device?

The use of the supplied hold-down device is generally recommended and generally ensures that loads prone to tipping are fixed and stabilized and extends the gripping range for medium and small load geometries. Small loads must only be gripped in conjunction with the hold-down device. Small loads are defined as loads with a small diameter that do not rest against the casing of the CSFR G2 150 when the gripper jaws are fully closed. In addition, the use of the hold-down device is essential when gripping long loads that are longer than 80 cm. In exceptional cases, the use of the hold-down device can be dispensed with. For example, for loads that have a short load length and a sufficiently large load diameter and are therefore not prone to tipping, or when using several CSFR G2 150s connected in series on a crossbeam.

What is the permissible load capacity of the CSFR G2 150?

Loads with a dead weight between 20 and 150 kg can be handled safely with the CSFR G2 150 universal gripper.

Can I also handle loads under 20 kg?

Yes. Loads under 20 kg can be handled after individual testing by the manufacturer.