With the Carl Stahl chain sling configurator, you can design your chain sling precisely for your application — in just six easy steps. From single-leg to four-leg slings, with or without a wreath/auxiliary chain: the configurator guides you through every option — including a 3D view, WLL verification, and component comparison.

Your benefits at a glance:

- Guided 6-step process with safety notices according to DGUV 100-500 / 109-017

- Interactive 3D visualisation

- Selection by working load limit, number of legs, and effective length

- Compare components (e.g. shortening elements, connectors, hooks)

VIP or ICE – what’s the difference?

In the configurator you can choose between two high-performance RUD technologies: VIP (Grade 10) and ICE (Grade 12). Both stand for top quality, safety, and traceability. The following guide helps you select the right option.

VIP – Grade 10: the robust all-rounder

- Up to 30% higher WLL compared to Grade 8 at the same chain diameter

- Considerably lighter due to optimised chain dimensions and material strength

- Exceptional toughness thanks to specially tempered CrNiMo alloy steel

- Durable pink powder coating with heat indicator (changes colour above 200 °C)

- DNV-approved for marine, industrial and offshore applications

- Outstanding wear resistance through RUD’s precision heat-treatment process

ICE – Grade 12: maximum performance at minimal weight

- Up to 60% higher breaking force than Grade 8 — ideal for heavy loads

- Roughly 30% lighter, providing ergonomic handling and improved safety

- Temperature-resistant from –60 °C to +300 °C for extreme operating environments

- High surface hardness and wear resistance through special ICE hardening

- Suitable for extreme conditions: cold, heat, sharp-edged loads

- Resource-efficient and sustainable thanks to optimised alloy and energy use

Conclusion:

VIP is the proven choice for versatile applications with dynamic loads. ICE is ideal when you work in particularly harsh or extreme conditions — and value low weight with maximum breaking strength.

VIP vs. ICE – decision aid for your application

|

|

|

|---|---|---|

| Feature / property | VIP – Grade 10 | ICE – Grade 12 |

| Manufacturer | RUD | RUD |

| Working load limit | Up to 30 % higher than Grade 8 | Up to 60 % higher than Grade 8 |

| Self-weight | Reduced vs. Grade 8 | Approx. 30 % lighter than Grade 8 |

| Material | Specially tempered alloy steel | ICE special alloy |

| Temperature range | –40 °C to +200 °C | –60 °C to +300 °C |

| Surface finish | Pink coating with heat indicator | ICE pink with temperature indicator |

| Wear resistance | High | Very high |

| Optional corrosion protection | Corrud® DS | Available on request |

| Traceability | Batch numbers/embossing | Quality stamp “D 1–12” |

| Approvals | DNV available | Conforms to DIN EN 818 / 1677 |

| Ergonomics & handling | Lighter than Grade 8 | Highly ergonomic |

| Recommended use | Versatile all-rounder | Extreme conditions & heavy duty |

| Typical applications | Mechanical engineering, logistics, production | Offshore, ports, cold/heat, heavy loads |

Configurator highlights at a glance: what to keep in mind

The configurator guides you step by step to a safe selection. For planning, operation, and inspections, please note:

1. Load weight

The weight to be lifted is the basis of any design. Only an accurate weight (including attachments) allows you to determine the safe WLL.

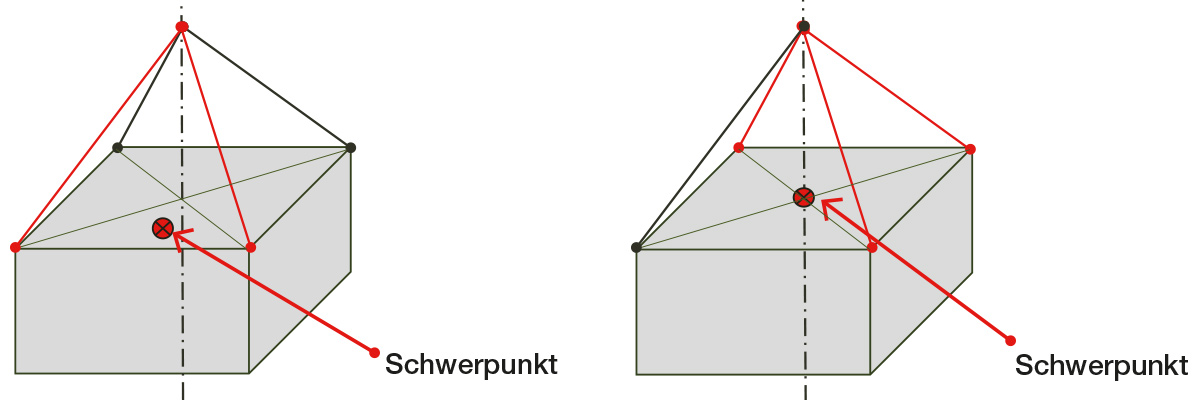

2. Number of legs & symmetry

Up to four legs are possible. The number depends on attachment points, symmetry, centre of gravity, and load geometry. For unsymmetrical loading, the WLL of a single leg applies (DGUV 100-500).

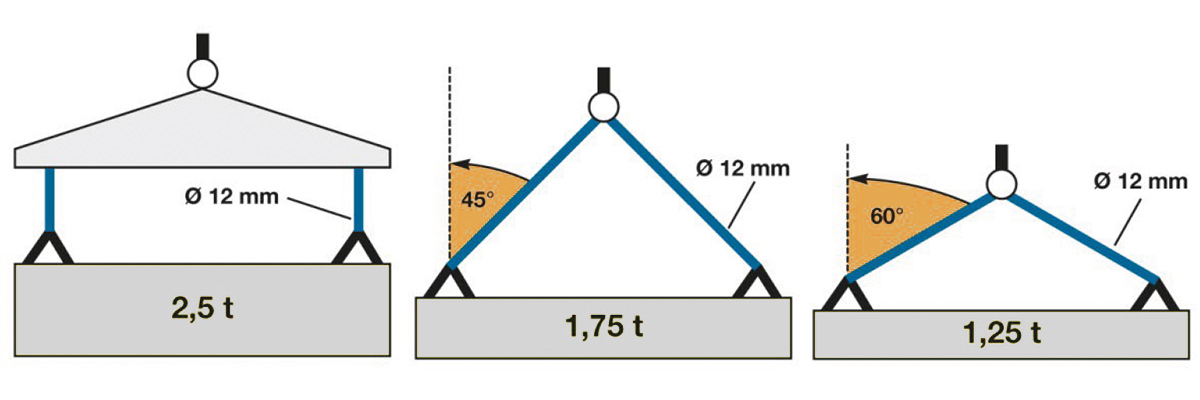

3. Effective length & sling angle

Effective length determines the sling angle (permitted 0°–60°). A larger distance between attachment points requires longer legs. The configurator checks angles and shows WLL depending on angle.

4. Centre of gravity & geometry

For asymmetrical or elongated loads, different leg lengths or additional components (e.g. wreath/auxiliary chain) may be required. Observe any WLL reductions.

5. Operating environment

Temperature, cold, moisture, or edges influence the choice of grade. ICE components are suitable, for example, from –60 °C to +300 °C; sharp-edged loads require suitable edge protection.

6. Safety, combinations & prohibitions

Only combine components of the same grade/nominal diameter. Knots, twists and choking with hoist chains are not permitted. The configurator flags incompatibilities and guides you to a safe selection.

Go to the configurator

Order standard lengths online

Many applications are covered by our stocked standard lengths. Discover selected sets in the webshop — fast delivery, RUD quality, including certification.

Do you have special requirements or questions?

Our specialists are happy to support you — from choosing the right grade (VIP/ICE) and sizing to documentation. Use the form and we’ll get back to you shortly.

Get in touch

Write to us about your application, product selection, or the configurator — we’re here to help.