If you transport heavy round material such as slit strip, you usually use steel straps, belts, wooden wedges or develop your own solution. However, it is more than questionable whether the round material is really well secured with these. This means a risk, because if it is secured incorrectly, both employees and the material itself are put at risk. And anyone who has already had to replace complete slit strips because the material was damaged during transport will wish for a better solution by then at the latest.

At the same time, the handling of slit strip can be implemented much more safely and efficiently. With a transport system specially developed for this challenge, you can improve your workflows and no longer struggle with inappropriate securing and transport solutions.

When transporting heavy round material such as slit strip, manufacturers, transport companies as well as the processing companies regularly face the following problems.

On loading platforms of transport vehicles, slit strip must be just like other loads, well secured. Since it is a round material, you must keep the load from rolling away, or transport it lying down. Straps, wooden wedges or other securing devices work, but are not ideal. A means of transport especially for slit strip simplifies securing immensely.

The surface and edges of the slit strips can bend and scratch very easily. It is therefore important to choose a suitable means of transport. With one of these, the slit strips are stored in such a way that they cannot move freely, but nevertheless too much pressure is not exerted.

Slit strips are unwieldy and are usually stored and transported lying down. To use them, the belts would therefore always have to be erected. If the slit strips aretransported and stored standing up, this therefore saves time. The material can be fed into the machine standing up and unrolled directly.

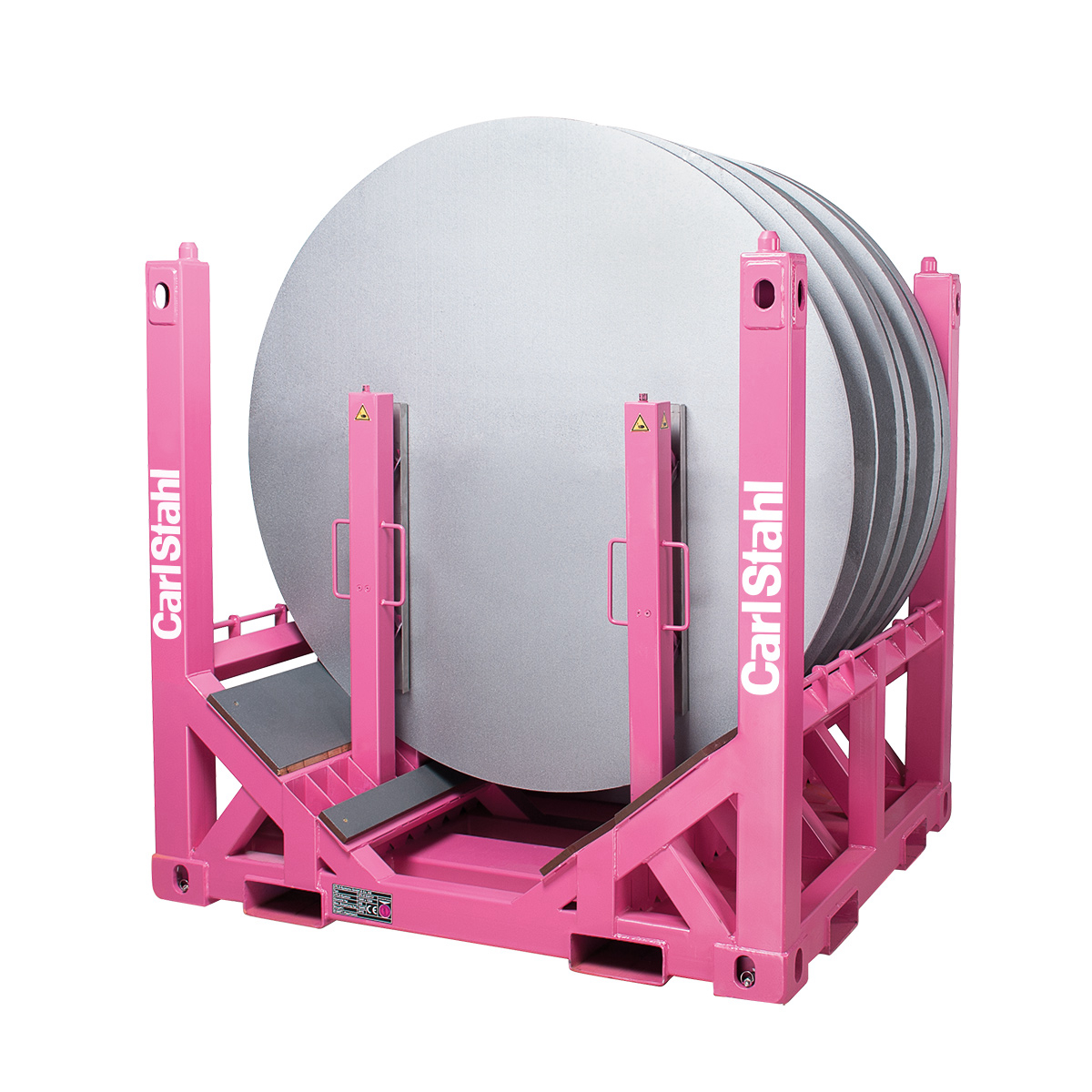

Don't settle for workarounds and slow or insecure workflows. Instead, opt for an innovative option. The Universal Transport and Storage System (CSCH) supports both the (intra-)logistics and the storage of slit strip.

From the manufacturer to the forwarding agent to the processing on the machine, the CSCH solution improves the work with slit strip. The advantages are manifold.

The CSCH system is perfect for the safe transport of slit strip - for two reasons: On the one hand, the load is fixed inside the device without attacking the material. But also the CSCH itself is designed in such a way that it can be secured well on loading areas.

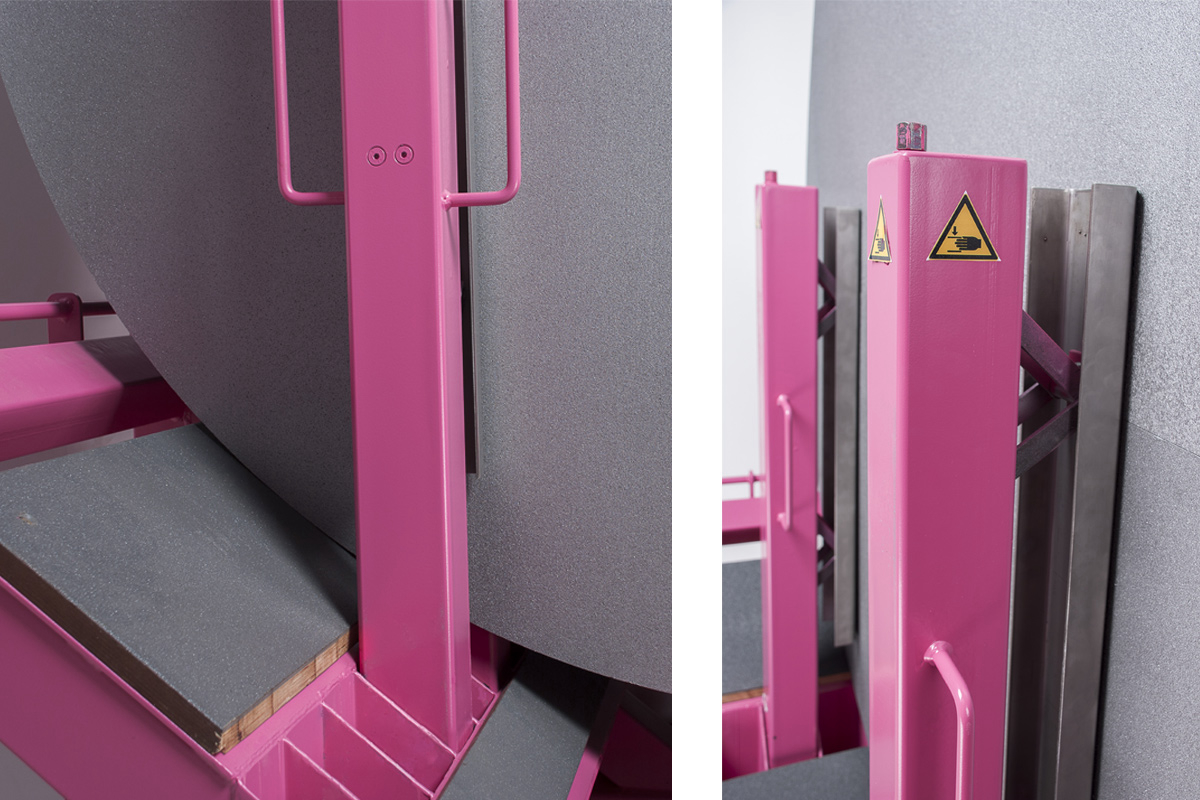

The slit strips stand in the CSCH in such a way that they cannot be damaged. All components that come into direct contact with the material are provided with a plastic protection. The securing stanchions - i.e. the supports or locks for the slit strips - can be exchanged and selected to suit the respective slit strip.

The CSCH are designed for efficient workflows. The slit tapes can be transported and stored upright in the system, which is why you can use them in a practical way. In addition, the storage and transport equipment is designed in such a way that you can either attach chassis and move the entire constructions in this way, or the CSCHs can be moved by crane or forklift. The CSCHs are also available in stackable versions, which can simplify storage and transport even more.

The CSCH frames are available in different versions that can transport different sizes and weights. The securing stanchions can also be exchanged. In addition, the system can be combined with other load lifting devices. This gives you full flexibility when working.

The CSCH is approved by TÜV Süd and certified by the DGUV. In addition, the system complies with the DIN ISO 1161 standard, so you are also legally on the safe side and do not have to fear any penalties due to unsafe makeshift constructions.

In order to be able to use slatted belts, they must stand or hang upright. With classic solutions, transport and storage take place lying down. They must therefore always be turned over for use. This is time-consuming and involves the risk of accidents and damage. With the CSCH, the slit strips are always in an upright position - both during storage and transport.

One of the advantages of the Carl Stahl CoilHandling System (CSCH) for slit strip is that they are suitable for every step in the logistics chain. The manufacturer can store them in the CSCH directly after production and hand them over to the freight forwarder. The latter transports the slit strips to the processing company, where they are stored in the system and can be used directly from it. In principle, slit strips no longer have to leave the transport rack.

Slit strip is an important resource for many companies. But the material can only be used if it arrives at the processing plant without damage. So if only to cause less damage when transporting slit strip, you should choose a safe solution. But even more important than protecting the material is the health of those who have to work with the material being transported. To prevent accidents at work, slit strip must be secured at all times - i.e. during transport, storage and use. With a CSCH, this is no problem.